The outstanding braking power of Trickstuff brakes results from the interaction of various factors. Among other things, the choice of brake pads and discs in terms of material, surface area and friction coefficient is essential for braking performance. In addition, braking performance depends decisively on the hydraulic and mechanical transmission ratios, which directly influence the braking force. The higher the transmission ratio, the stronger the braking effect. At this point, the stiffness of the overall system also plays a crucial role. As the braking force increases, the demands on the stiffness of the individual components such as brake calipers and brake hoses also rise.

braking power

HYDRAULIC TRANSMISSION RATIO

The hydraulic transmission ratio refers to the ratio of the piston surfaces of the pump piston to the caliper pistons. The ratio determines the force that is transmitted to the brake pads. The higher the transmission ratio, the greater the braking force at a given input force, whereby the diameter of the pistons has a crucial influence on the braking power.

All Trickstuff brakes are equipped with a 9mm pump piston which enables a higher hydraulic transmission ratio compared to conventional 10mm pump pistons. The size and number of caliper pistons differs depending on the brake model and intended use.

MechanicAL TRANSMISSION RATIO

The mechanical transmission ratio describes the power transmission from the brake lever to the brake pump. Trickstuff brake levers and pumps are designed differently depending on the area of application and transmit the braking force either linearly or progressively. The type of power transmission has an influence on the braking experience, which can be assessed according to individual preference.

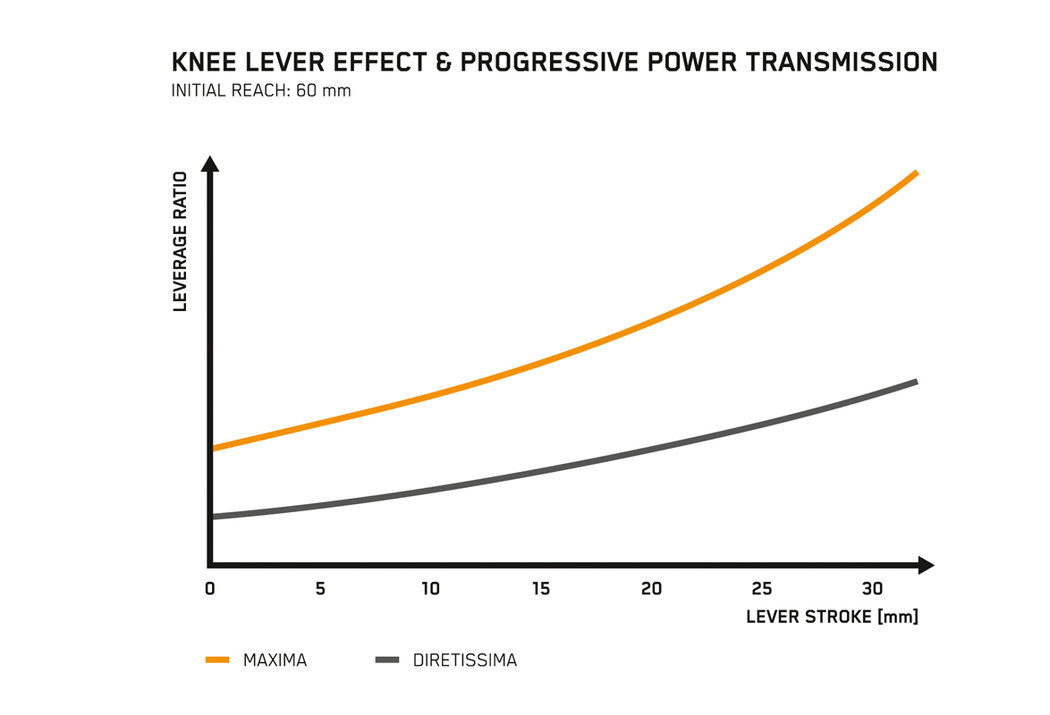

Knee lever effect and progressive power transmission

A knee lever describes the kinematics of two levers that are connected to each other by a joint. The special feature of the knee lever is the travel-dependent transmission ratio. For a brake lever with knee lever effect, the geometry of the brake pump and lever is designed in such a way that the transmission ratio increases as the lever is pulled. Thus, the braking force does not increase linearly, but rises progressively as the lever is operated, allowing the brake to be applied very sensitively and, depending on the riding situation, to slow down gently or generate significant braking force.

Furthermore, the kinematics reduce the amount of force required on the brake lever. Particularly on long descents and when braking frequently and forcefully, the knee lever reduces the input force that is needed and counteracts cramping of the arms. Goodbye, armpump.

Linear power transmission

With linear power transmission, the braking force is transmitted proportionally from the brake lever to the brake system. This means that the brake develops its full braking effect as soon as the pressure point is reached and increases steadily as the finger lever is applied more firmly. The development of the braking force is therefore predictable and easy to adjust, so that you can quickly get used to the feel of the brakes.